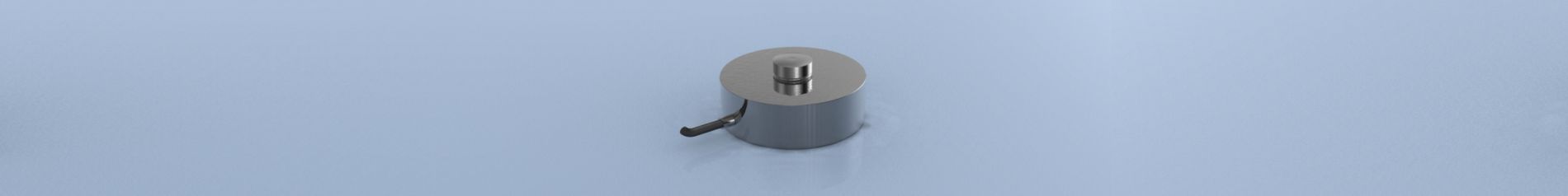

CDIT-1

- 50kg bis 5te

- Niedrige Höhe/Profil

- Konstruktion aus rostfreiem Stahl

In den meisten industriellen Umgebungen gibt es Hunderte von Schrauben, die Geräte und Maschinen an ihrem Platz halten. Einige dieser Schrauben sind entscheidend für den sicheren Betrieb der Maschinen und damit auch für die Sicherheit der Arbeiter, die sie bedienen. Sollten diese wichtigen Schrauben versagen, kann dies zu Maschinenschäden, Produktionsausfällen und sogar zu Verletzungen des Personals führen. Daher ist es wichtig, dass die Schrauben richtig angezogen werden, da ein zu starkes Anziehen zu einer vorzeitigen Ermüdung und zum Versagen der Verbindungen führen kann; bei einer zu geringen Spannung könnten sich die Verbindungen lösen. In den meisten Fällen hängt das korrekte Anziehen von den Fähigkeiten des Bedieners ab und ist daher fehleranfällig.

LCM Systems stellt Unterlegscheiben/Schraubenspannvorrichtungen her Kraftaufnehmer , die zur Verbesserung der Genauigkeit des Schraubenspannvorgangs verwendet werden können und somit die Zuverlässigkeit und Sicherheit der Infrastruktur verbessern. Die Überwachung der Dichtheit im Laufe der Zeit wird zu einer einfachen Übung und macht eine physische Inspektion und ein mechanisches Ablesen des Drehmoments jeder Schraube überflüssig. Dies ist besonders nützlich für schwer zugängliche Schrauben.

Unsere WAS Kraftaufnehmer sind einfach und schnell zu installieren und können eine kontinuierliche Spannungsüberwachung bieten. Wir können nur die Kraftaufnehmer und ein Handheld-Display für regelmäßige Überprüfungen liefern oder ein umfassenderes System, das Instrumentierung mit Alarmen beinhaltet, um die Eigentümer der Anlage zu alarmieren, wenn die Spannungen vordefinierte Grenzen über- oder unterschreiten.

Zusätzlich zu unserem WAS Schraubenspannungsmessung Kraftaufnehmerbieten wir auch mehrere andere Kraftaufnehmer an, die für die Überwachung der Schraubenspannung verwendet werden können. Siehe unten für weitere Details zu diesen und unserem WAS Kraftaufnehmer.