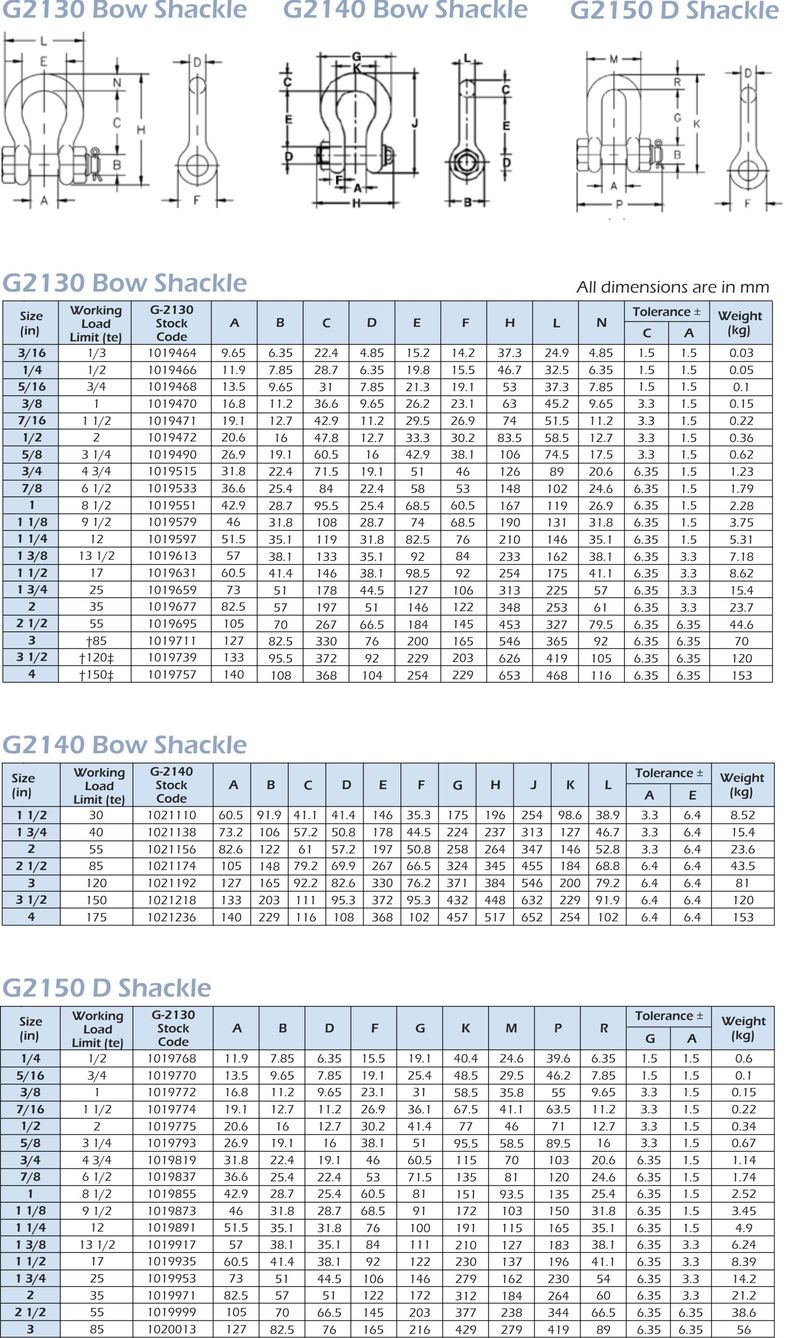

G2130, G2140, G2150 Crosby Sicherheitsschäkel

G2130 Bügelschäkel & G2150 D-Schäkel

- Fassungsvermögen 1/3 bis 150 Tonnen, Klasse 6.

- Tragfähigkeitsgrenze und Güteklasse "6" dauerhaft auf jedem Schäkel angegeben.

- Geschmiedet ¯ abgeschreckt und vergütet, mit legierten Stiften.

- Feuerverzinkt oder selbst eingefärbt. (85, 120 und 150-Tonnen-Schäkel sind alle feuerverzinkte Bögen und die Bolzen sind Dimetcoted® und rot lackiert)

- Ermüdungsfestigkeit (1/3t - 55t).

- Schäkel mit einem Gewicht von 25 t und mehr sind RFID-ausgerüstet.

- Zugelassen für den Einsatz bei -40 Grad C (-40 Grad F) bis 204 Grad C (400 Grad F).

- Bügel und Bolzen von 2t bis 25t sind zertifiziert, um den Charpy-Schlagversuch von durchschnittlich 42 Joule (31 ft-Ibs.) bei -20 Grad Celsius (-4 Grad F) zu erfüllen.

- Erfüllt oder übertrifft alle Anforderungen der ASME B30.26.

- Die Größen 1/2t-25t entsprechen den Leistungsanforderungen der EN13889:2003.

- Schäkel mit einem Gewicht von 55 Tonnen und weniger können mit Zertifikaten nach bestimmten Normen wie ABS, DNV, Lloyds oder anderen Zertifizierungen versehen werden, wenn dies zum Zeitpunkt der Bestellung gewünscht wird.

- Schäkel mit einem Gewicht von 120 Tonnen und mehr werden geprüft, mit Magnetpartikeln inspiziert und mit einem serienmäßigen Bolzen und Bügel versehen.

- Typenzulassung und Zertifizierung gemäß ABS 2006 Steel Vessel Rules 1-1-17.7 und ABS Guide for Certification of Cranes.

- 3.1 Standardzertifizierung für Charpy- und statistische Prüfungen bis zu 25 Tonnen nach DNV2.7-1 und EN13889 verfügbar.

- Crosby 2t bis 25t G2130 Ankerschäkel sind gemäß DNV-Zertifizierung typgeprüft

- Anmerkungen 2.7-1- Offshore-Container. Diese Crosby-Schäkel sind statistisch geprüft und stoßgeprüft. Die Tests werden von Crosby durchgeführt und ein 3.1 Testzertifikat ist auf Anfrage erhältlich.

- Alle anderen 2130er und 2150er Schäkel können auf besondere Anfrage die Charpy-Anforderungen von durchschnittlich 42 Joule (31 ft-Lbs) bei -20 Grad C (-4 Grad F) erfüllen.

G2140 Bugschäkel

- Abgeschreckt und gehärtet.

- Legierte Bögen, legierte Bolzen.

- Geschmiedeter legierter Stahl 30 bis 175 metrische Tonnen. Gegossener legierter Stahl 200 bis 400 Tonnen. Erfüllt die Leistungsanforderungen von Schäkeln der Güteklasse 8.

- Die Belastungsgrenze ist auf jedem Schäkel dauerhaft angegeben.

- Die 30-, 40-, 55- und 85-Tonnen-Schäkel sind verzinkt oder einfarbig mit verzinkten und rot lackierten Bolzen erhältlich.

- 120, 150, 175 Tonnen schwere Schäkelbügel sind feuerverzinkt; Bolzen sind Dimetcoted® und rot lackiert.

- Die Bügel der 200, 250, 300 und 400 Tonnen schweren Schäkel sind aus Dimetcoted®; die Bolzen sind aus Dimetcoted® und rot lackiert.

- Alle Größen sind RFID-ausgerüstet.

- Zugelassen für den Einsatz bei -40 Grad C (-40 Grad F) bis 204 Grad C (400 Grad F).

- Die Schäkel sind vergütet und erfüllen die DNV-Aufprallanforderungen von 42 Joule (31 ft-lbs.) bei -20 Grad Celsius (-4 Grad F).

- Alle Größen werden einzeln auf das 2,0-fache der Arbeitsbelastungsgrenze geprüft.

- Schäkel mit einem Gewicht von 200 Tonnen und mehr werden mit einem serienmäßigen Bolzen und Bügel, einer Materialzertifizierung (chemisch) und einer Magnetpartikelprüfung geliefert. Bitte beachten Sie, dass die Zertifizierung zum Zeitpunkt der Bestellung angefordert werden muss.

- Erfüllt oder übertrifft alle Anforderungen der ASME B30.26, einschließlich Kennzeichnung, Duktilität, Auslegungsfaktor, Prüflast und Temperaturanforderungen. Wichtig ist, dass diese Schäkel weitere kritische Leistungsanforderungen erfüllen, wie z. B. Ermüdungslebensdauer, Aufpralleigenschaften und Materialrückverfolgbarkeit, die in der ASME B30.26 nicht berücksichtigt werden.

- Typenzulassung und Zertifizierung gemäß ABS 2006 Steel Vessel Rules 1-1-17.7 und ABS Guide for Certification of Cranes.

- Bolzen und Bögen aus Legierung

- Bogenfesseln von 0,3te bis 400te

- Kaufen Sie als Zubehör mit oder ohne unseren Link Kraftaufnehmer

- D-Schäkel von 0,5te bis 85te

- Hergestellt von Crosby

- Abgeschreckt und vergütet

- Lieferung mit vollständiger Rückverfolgbarkeit durch Crosby

Bitte lesen Sie das Produktdatenblatt, indem Sie hier klicken

- Heben

- Kabelspannung

- Liegeplatz

- Pull-Test